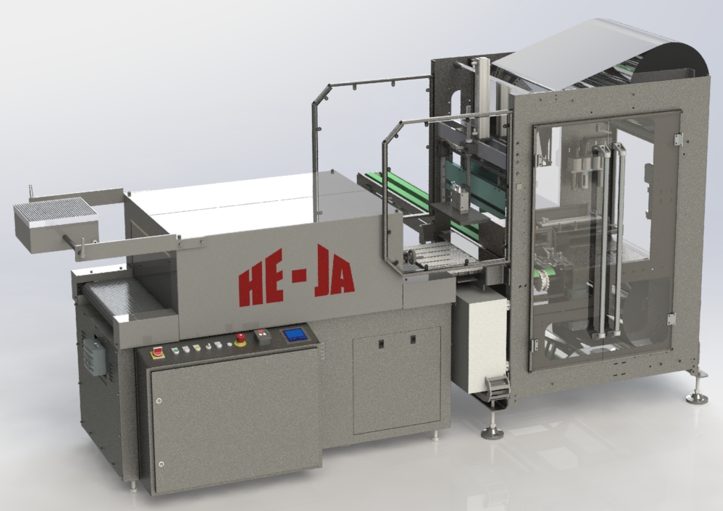

HE-JA Shrink tunnel

The company He-ja is specialized in shrink tunnel construction suitable for your product and offers a total of 40 different tunnel variants for dry as well as wet rooms. Our standard hood width is 500-1500mm wide and our standard tunnel lengths are 1,800, 2,200, 2,800 and 3,600mm. Should your product require a special solution, we will certainly find the right technical design for it.

The heating power is between 15-36KW depending on the size of the hood and tunnel length. Our bestseller shrink tunnel type T600 with a total length of 1.800mm (hood length 1.200mm) and a hood height up to 300mm shrinks 80my PE shrink films without any problems with a heating power of 15KW at a capacity of up to 10 repackages/min. Thanks to the sophisticated technical design of the control components and the perfect balance between air flow and temperature, you can achieve top values in your energy balance. The actual consumption is reduced by up to 35% in production operations.